This is the multi-page printable view of this section.

Click here to print.

Return to the regular view of this page.

Coding Scenarios

A coding scenario defines a linear sequence of actions that are triggered by a specific input, such as an import task or a signal from an I/O device. Each action is represented by a step and steps can be freely dragged and dropped in the pipe.

Note

Some steps have obligatory or optional parameters which you can use to further specify the action of the step. Click on a step after adding it into the pipe to show the list of available parameters. Steps with unset obligatory parameters are highlighted red after you add them into the pipe.

For more information, see Overview - Steps of a Coding Scenario.

1 - Creating a Coding Scenario

Creating and configuring a coding scenario on a production line.

Before you begin

- You are assigned to a user group that at least has the permission Configure hardware.

- You have created a production line and assigned devices to it.

- You have imported or manually added master data.

- You have uploaded and mapped all label layouts that you want to use in the coding scenario.

About this task

To create a coding scenario, you define a set of steps that a production line must follow depending on the received input.

Procedure

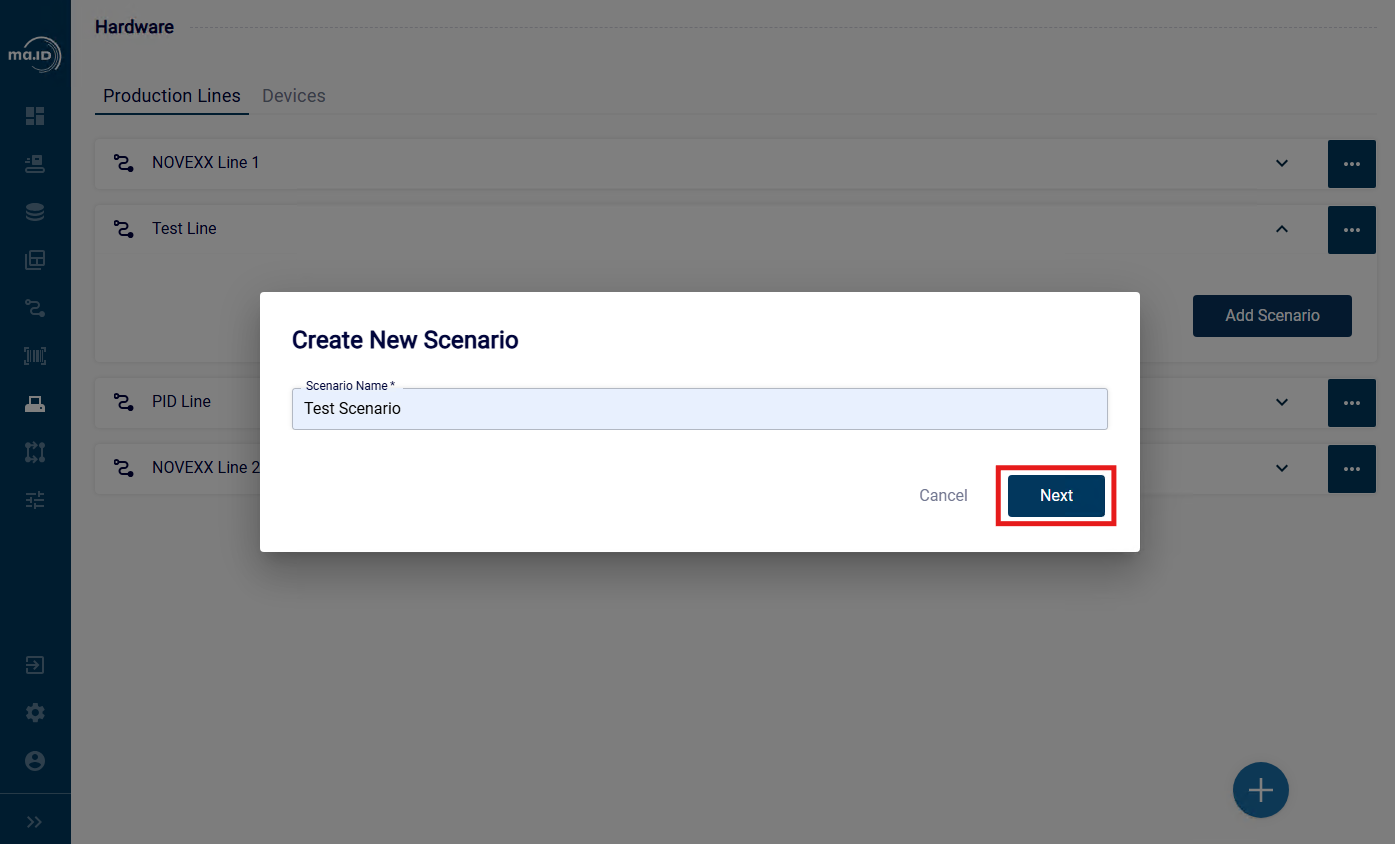

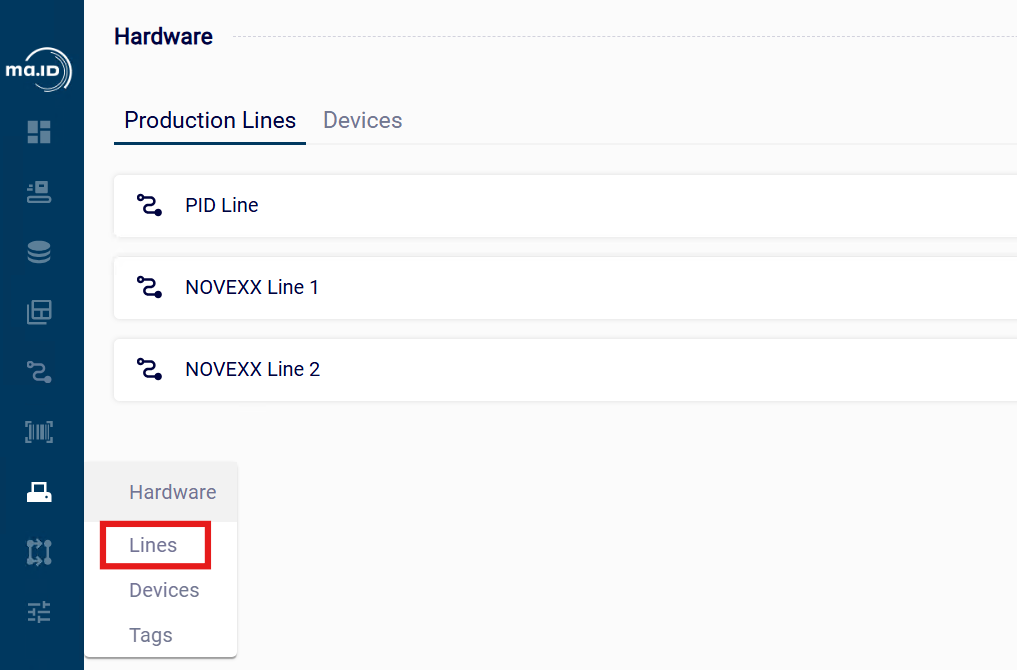

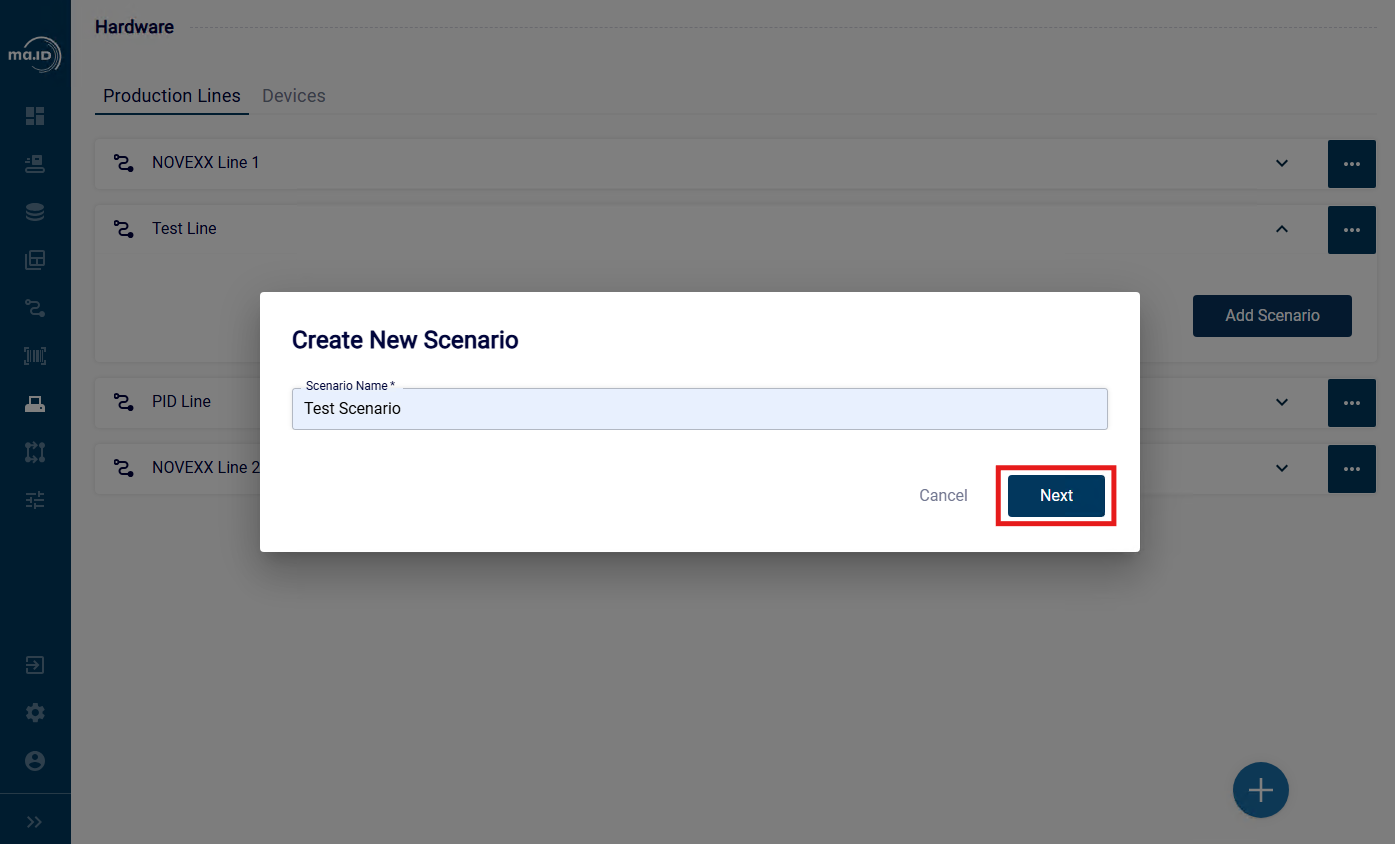

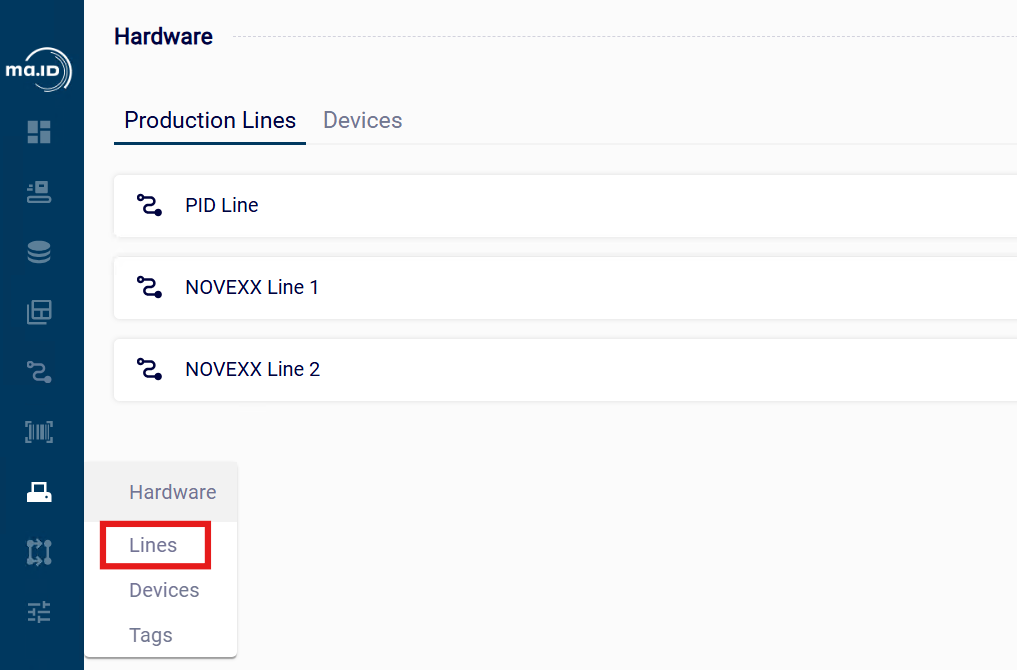

- On the side bar, select Hardware, and click Lines.

The view Production Lines opens. You see the overview of the production lines that are already available in manage.ID.

The view Production Lines opens. You see the overview of the production lines that are already available in manage.ID.

- Click the arrow icon on your production line to expand it.

- Click Add Scenario.

The window Create New Scenario opens.

- Enter a unique name for your coding scenario and click Next.

Tip: Enter a name that describes the task you want to execute with the coding scenario, for example, “pallet labeling”.

You have created a coding scenario and you see the overview of the coding scenario that is currently empty.

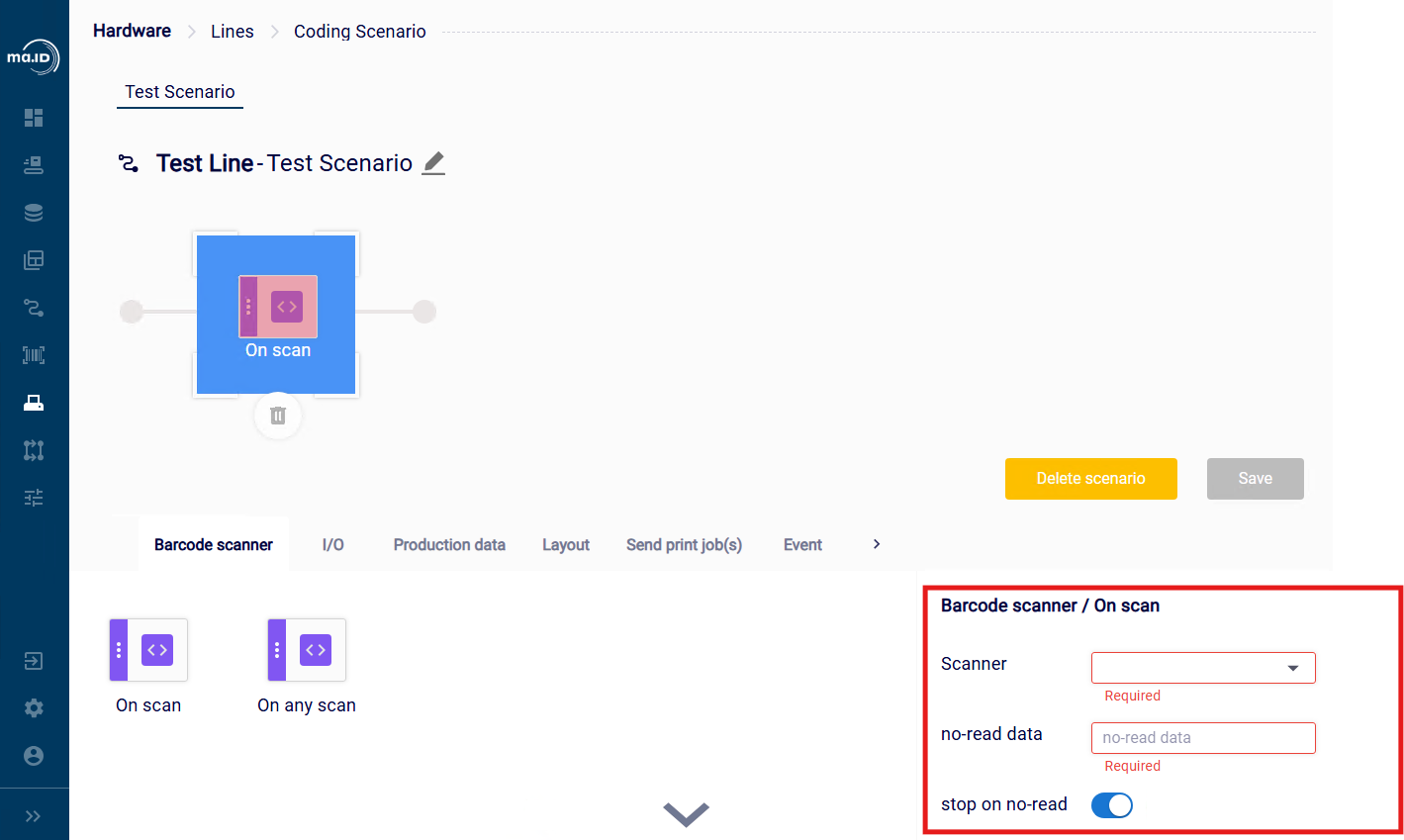

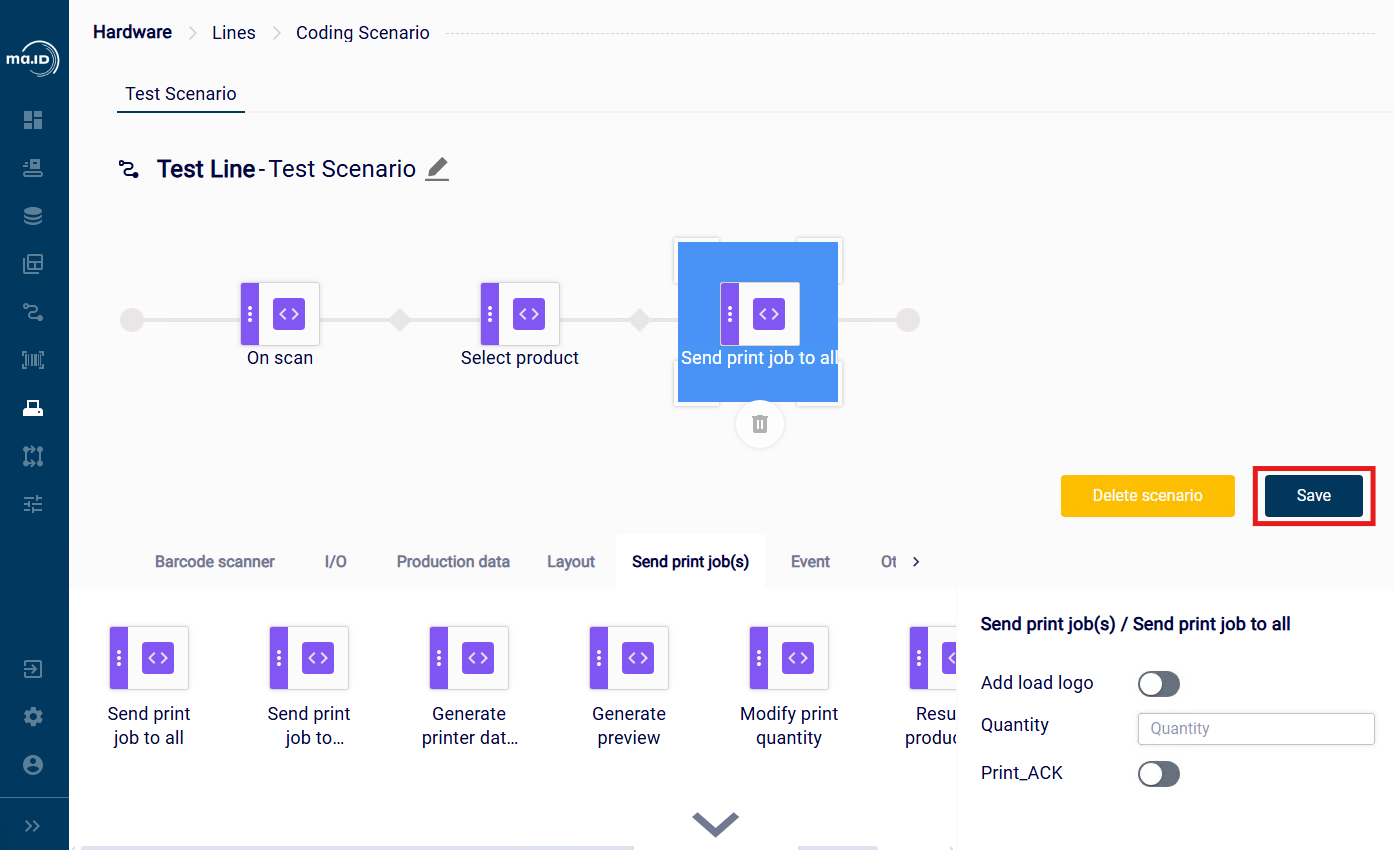

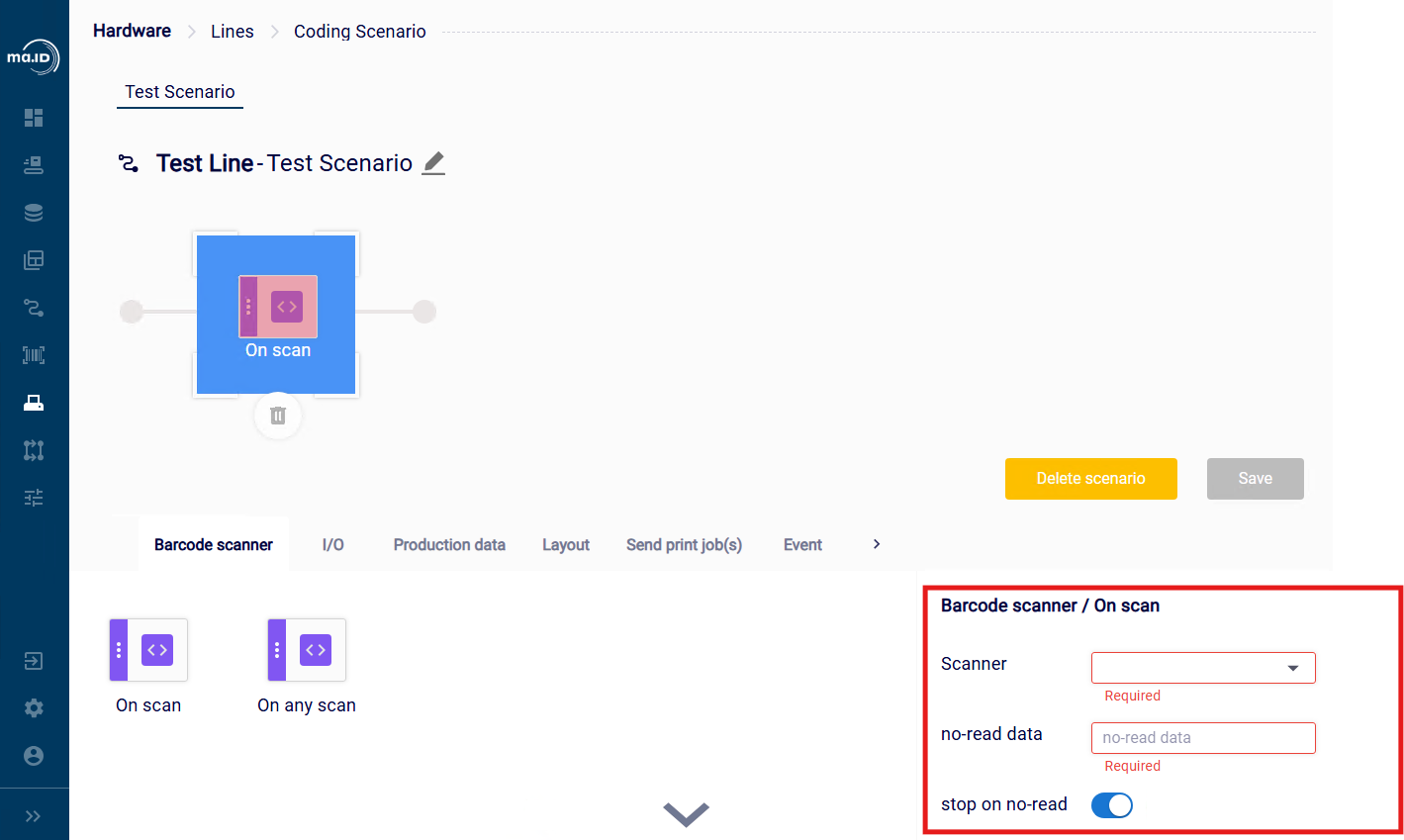

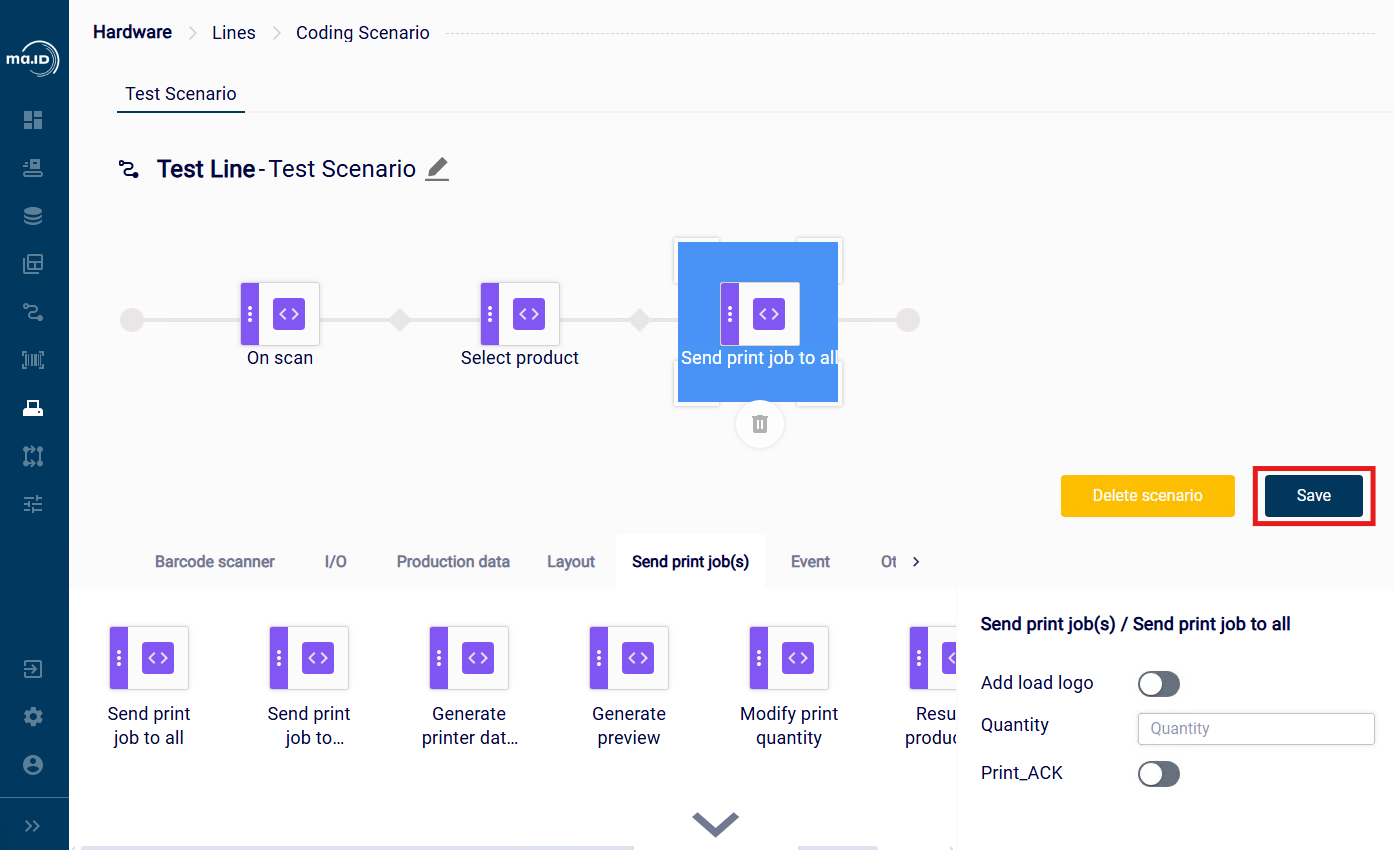

- To configure the coding scenario, drag a step from a tab and drop it on the pipe.

- Set the parameters for the step. For more information on steps and their parameters, see Overview - Steps of a Coding Scenario.

- Repeat steps 5 and 6 to add more steps.

- Click Save & Activate.

Results

You have created, configured and activated a coding scenario.

What to do next

- Prepare production on a production line.

2 - Overview - Steps of a Coding Scenario

Overview of the available steps for a coding scenario.

Barcode scanner

This tab provides steps that process input from a scan.

On scan

This step waits for an incoming scan from a specific scanner in the production line.

The parameter Scanner sets the name of the scanner that is tracked by the step.

On any scan

This step triggers the next step as soon as any of the scanners in the production line delivers a scan.

I/O

This tab provides steps that either receive an I/O signal as an input or trigger a function of an I/O device as an output.

On I/O

This step waits for a specific I/O signal from a specific I/O device.

Set I/O

This step sets an I/O signal of a specific I/O device into a specific status.

Reset I/O

This step resets an I/O signal from a specific I/O device.

Each I/O step has two parameters:

- I/O device: The name of the I/O device that is tracked or controlled by the step.

- Aliases: The name of the specific signal emitted by an I/O device.

All I/O steps except On I/O have the additional parameter signal-duration, which you use to define the duration of the I/O signal.

Production data

This tab provides steps that process received master data.

Select product

This step identifies the product from the master data that is fed into the production line.

Select production order

This step identifies the order from the master data that is fed into the production line.

Collect list of products

This step selects the product from a specific field in the master data that is fed into the production line.

Collect list of orders

This step selects the order from a specific field in the master data that is fed into the production line.

The steps Collect list of products and Collect list of orders have two parameters:

- Field to filter: The name of the field in the master data that carries the relevant information.

- Filter regular expression: A regular expression that is applied to the applied filter.

Layout

This tab provides steps that process layout information.

Identify layout for the printer

This step identifies the name of the label layout(s) from a specific field in the product data that is fed into the production line.

The parameter Layout name table sets the name of the table in the master data that carries the column with the name of the label layout(s).

The parameter Layout name column sets the name of the column in the table in the master data that carries the name of the label layout(s).

Send printjob(s)

This tab provides steps that control printing processes.

Print to all

This step starts a printing process on all printers in the production line.

Send printjob to printer

This step starts a printing process on a specific printer in the production line.

The parameter Printer sets the name of the printer that should start printing.

Generate printer data set(s)

This step creates data sets to log printing processes on the production line.

The parameter LDF table sets the name of the LDF table that is used.

The parameter LDF column sets the name of the column in the selected LDF table that is used.

The parameter LFM file name sets the name of the LFM file that is created.

Event

This tab provides steps that react to changes in master data.

Product change

This step reacts to a change of the product in master data.

Order change

This step reacts to a change of the order in master data.

Product or Order change

This step reacts to a change of the product or the order in master data.

Data import

This step reacts to the execution of a specific import task.

- The parameter Import interface sets the name of the import task that is tracked by the step.

- The parameter Start by success defines whether a successful execution of the import task is mandatory to trigger the next step.

Other

This tab provides miscellaneous steps.

Sync files on all labelers

This step synchronizes all files on the hardware devices on the production line.

Pause

This step pauses the operation of the production line.

- The parameter Sleep (sec) sets the amount of time for which the production line should pause in seconds.

The view Production Lines opens. You see the overview of the production lines that are already available in manage.ID.

The view Production Lines opens. You see the overview of the production lines that are already available in manage.ID.